The multi-station progressive die is an advanced and efficient stamping die in the stamping die. It is a multi-process integrated die developed on a single-process stamping die. For some stamping parts with complex shapes and multiple processes such as punching, bending, forming, and deep drawing, they can be punched on a pair of multi-station progressive dies. Multi-station progressive die is an automatic and semi-automatic production equipment, and it is an advanced die structure form to ensure stable stamping quality. A reasonable mold structure must not only ensure the various technical indicators of the produced products, but also shorten the mold manufacturing cycle and reduce the mold manufacturing cost, so as to meet the requirements of modern industrial production for high-quality, high-efficiency, and low-cost molds.

Composition of multi-station progressive die

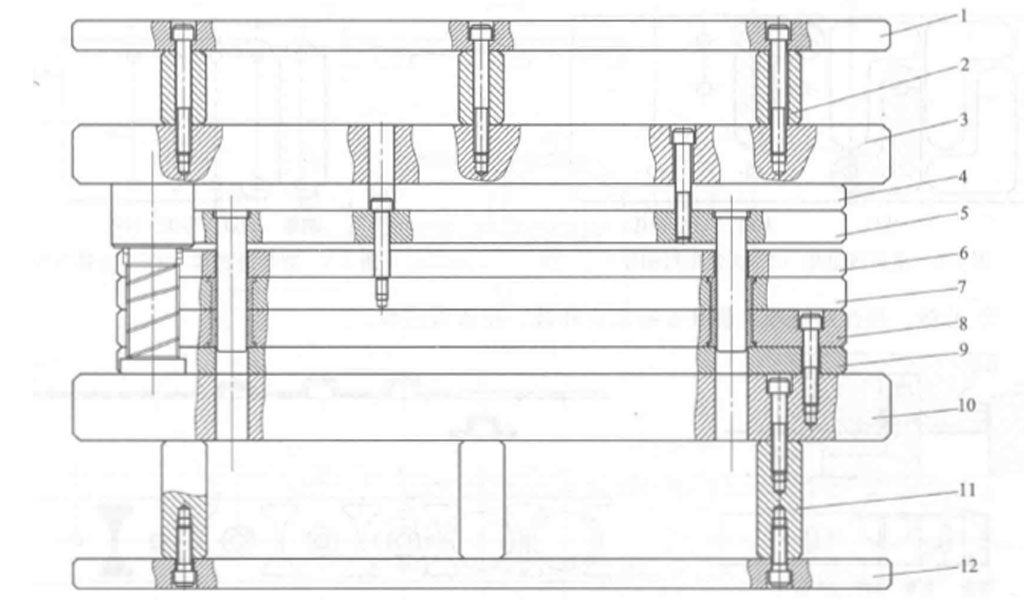

The schematic diagram of the progressive die structure is shown in Figure 1-1. Generally, this structure is used in large molds. For small or medium and large molds with low closing height, there is no need to use upper pallets, upper feet, lower feet, and lower pallets. template

The selection principle of the thickness: consider the length of the spring, the length of the standard punch, the thickness of the die and the height of the closed mold. A complete progressive die is divided into upper die and lower die. When working, the upper die is connected with the press slider and moves up and down with the press slider. The small and medium-sized molds are connected with the slider of the press by the mold handle (the large mold is fixed on the bottom plane of the slider with a pressure plate). The lower mold is fixed on the lower table of the press with a pressure plate, and the position cannot be moved during work.

- On the pallet:

- Upper block:

- Upper mold seat;

- Fixing plate backing plate:

- Fixing plate:

- Unloading plate backing plate:

- Unloading board:

- Look at the template:

- Formwork backing plate:

- Lower mold seat:

- About the block:

- Lower supporting plate

The upper die component of the progressive die

- Put on the pallet. The function of the upper supporting plate is to connect and fix the upper mold part on the slider of the stamping equipment through the clamp, so that the upper mold of the mold can move up and down with the stamping equipment.

- Put the block on. The upper pad is also called the upper mold foot or the upper pad foot. The upper spacer is located between the upper supporting plate and the upper mold base, and plays a role of heightening. Adjusting its height according to needs can make the mold suitable for different stamping equipment and ensure that the clamp has enough space for placement. The position of the upper pads will affect the entire stress situation, thereby affecting the working quality of the mold.

- Upper mold base. The upper mold base is the fixed plate of the upper mold part and the outer guide column or outer guide sleeve. When there is no upper supporting plate, it also has the function of upper supporting plate.

- Fixing plate backing plate. Also known as the upper backing plate. The backing plate of the fixed plate bears the active force of the punch to ensure that the spring has sufficient compression stroke.

- Fixing plate. Also known as the upper splint. The fixed plate is used for clamping and positioning the parts such as the punch and the small guide post.

- Unloading plate backing plate. The role of the stripper plate is to bear the impact load of the stripper assembly and the stripper insert.

- Unloading plate. The unloading plate plays the role of unloading, pressing and guiding. When the mold is closed, the unloading plate first presses the strip material (strip material) on the lower formwork to ensure that the strip material does not move, run or twist; when the mold is parted, the unloading plate plays the role of unloading.

The lower die component of the progressive die

- Lower the template. Also known as die fixing plate. The function of the lower formwork is to fix the insert of the die and press the strip material (strip) together with the stripper plate. It is also used as a cutting edge, and is usually called the die formwork.

- Lower formwork backing plate. Also known as die backing plate. The lower formwork backing plate bears the force of the die or die insert.

- Lower die base. The lower mold base is the fixed plate of the lower mold part and the outer guide sleeve or outer guide column (generally 5mm or 10mm thicker than the upper mold base).

- Lower block. Also known as the lower mold foot or the lower pad foot. The lower pad is located between the lower supporting plate and the lower mold base, which acts as a cushion and facilitates the discharge of waste materials. Adjusting this height according to needs can make the mold suitable for different stamping equipment. The arrangement of the lower pad will also affect the The stress status of the entire mold will affect the work quality and product quality of each template.

- Lower pallet. The function of the lower supporting plate is to connect and fix the lower part of the mold on the workbench of the stamping equipment through the clamper.