With the development of industrial technology, electrical control systems are becoming more and more common in the industrial field. The electrical control cabinet is the core component of the electrical control system, and whether its design is reasonable is related to the safety of the entire equipment.

In order to meet the manufacturing and use requirements of electrical control equipment, the following four steps of reasonable electrical control process design must be carried out.

understand The Craft

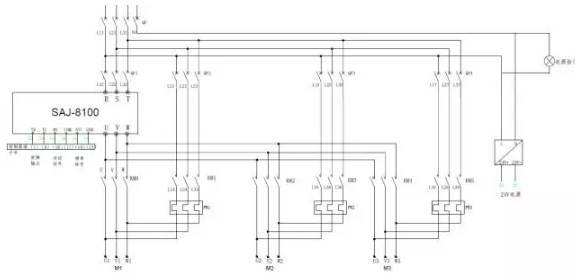

To design an electrical control cabinet, the first step is to understand the process and clarify the control logic. For example, if you design an 8100 one-to-many control cabinet, the required process is to work with one inverter to work with multiple water pumps. First, the frequency converter starts the 1# pump with frequency conversion. As the frequency increases, the pipeline pressure also increases. When the 1# pump reaches the maximum frequency and still cannot reach the target pressure, the system will switch the 1# pump to power frequency operation, and the inverter will switch to the 2# pump to start the 2# pump inverter, and so on.

Design Selection

After understanding the process, the next step is the selection of electrical components. The electrical components needed for the 8100 one-to-many control cabinet include: air switch, fuse, AC contactor, thermal relay, constant pressure water supply controller, switching power supply, etc. The rated capacity of the electrical components and the capacity of the wires are appropriately amplified according to the rated current of the water pump. For example, the rated current of the air switch is 1.5 times the rated current of the water pump.

Electrical Drawing Design

Electrical drawings include electrical schematic diagrams and electrical component layout diagrams.

Electrical schematic diagram: the purpose is to facilitate reading and analysis of control circuits, and should be drawn in the expanded form of electrical components based on the principles of simple structure and clear layers. It includes conductive parts and terminals of all electrical components, but is not drawn according to the actual arrangement of the electrical components, nor does it reflect the actual size of the electrical components. The electrical schematic diagram is generally divided into two parts: the main circuit and the auxiliary circuit (control circuit).

Electrical component layout: refers to the actual layout of electrical components in electrical equipment (reflecting the size of electrical components). Pay attention to the electrical layout:

- Separate strong and weak currents and pay attention to shielding to prevent external interference;

- The layout of electrical components should be neat and beautiful, and electrical components with similar dimensions and structures should be placed together;

- The electrical components should be arranged at a certain interval to facilitate heat dissipation.

Control Cabinet Wiring

- Use wire slots for wiring: When wiring through the wire slots, ensure that the joints between the wire slots are aligned, and try to avoid laying oblique wire slots;

- Fixed terminal block: The terminal block is generally arranged at the bottom of the control cabinet or console, and if there is a grounding copper strip, the grounding copper strip is installed at the bottom;

- Marking sleeve: for the same wire diameter, use the marking sleeve (special-shaped tube) with the same wire diameter to maintain the consistency of the text direction of all sleeves in a control cabinet, that is, the text on all horizontal and vertical sleeves The direction is the same, so that one is convenient to check the line, and the other is that it looks more regular.

Switchgear

The switch cabinet is a kind of electrical equipment. The outside line of the switch cabinet first enters the main control switch in the sheet metal fabrication cabinet, and then enters the sub-control switch. Each branch is set according to its needs. A combination of one or more low-voltage switchgear and related control, measurement, signal, protection, regulation, etc. equipment, all internal electrical and mechanical connections are completed by the manufacturer, and they are completely assembled together with structural components body. The main function of switchgear is to open and close, control and protect electrical equipment during the process of power generation, transmission, distribution and power conversion in the power system. The components in the switch cabinet are mainly composed of circuit breakers, disconnectors, load switches, operating mechanisms, transformers and various protection devices.

Structure and composition classification of switchgear

In order to protect personal and equipment safety, the switchgear is independently divided into several compartments in different ways. Compartment classification:

Busbar room: including horizontal busbar room and vertical busbar room functional unit room (switch compartment)

Cable outlet room: including the secondary equipment room of the cable room

The main components of the switchgear

Cabinet body: the shell skeleton of the switch cabinet and the internal installation and support parts.

Busbar: A low-impedance conductor that can be connected separately to several circuits.

Functional unit: All electrical equipment and mechanical components (including incoming and outgoing units) that perform the same function.

Incoming line (plug-in bus duct or cable) method

Upper incoming line; Bottom incoming line; Side incoming line; Rear incoming line.

Outlet mode (plug-in busbar or cable)

Classification of busbars:

Main busbar (horizontal busbar): the busbar connecting one or several distribution busbars and or incoming and outgoing line units.

Distribution busbar (vertical busbar): A busbar in the frame unit, which is connected to the main busbar and supplies power to the outgoing unit.

Classification of functional units

Fixed type: The connection of the main circuit can only be wired and disconnected when the switchgear is powered off.

Removable type (fixed separation type): It can be safely disconnected or connected from the main circuit when the main circuit is charged, and has connection and removal positions.

Withdrawable type: It can be safely disconnected or connected from the main circuit when the main circuit is charged, and has the positions of connection, test, separation and removal.

installation method

Installation location classification: indoor installation; outdoor installation.

Installation classification: installation against the wall; installation away from the wall.

Classification of fixing methods: bolt fixing; electric welding fixing.

Classification of low-voltage switchgear

GCS cabinet:

GCS type low-voltage withdrawable switchgear is used in three-phase AC frequency of 50Hz, rated operating voltage of 400V (690V), rated current of 4000A and below, as power in the power supply system, power distribution and centralized control of motors, capacitor compensation for. It is widely used in power plants, petroleum, chemical industry, metallurgy, textiles, high-rise buildings and other places. It can also be used in large power plants, petrochemical systems and other places with high automation and requirements for computer interface.

GCK cabinet: (MCC)

GCK low-voltage withdrawable switchgear (hereinafter referred to as switchgear) is composed of power distribution center (PC) cabinet and motor control center (MCC). The device is suitable for control and distribution systems with AC 50 (60) HZ, rated working voltage less than or equal to 660V, rated current 4000A and below, as power distribution, motor control and lighting and other power distribution equipment.

MNS cabinet: (MCC)

MNS low-voltage withdrawable complete switchgear (hereinafter referred to as switchgear) is an advanced low-voltage switchgear developed with reference to the design of foreign MNS series low-voltage switchgear (hereinafter referred to as switchgear) to meet the needs of the development of the power industry. ZBK36001-89 “Low-voltage withdrawable complete switchgear”, the international standard IEC439 stipulates that MNS type low-voltage switchgear can meet the needs of various power supply and distribution, and can be widely used in power plants, substations, industrial and mining enterprises, buildings, hotels, municipal construction, etc. A low-voltage power distribution system.

GGD Cabinet: (ESS)

GGD type AC low-voltage power distribution cabinet is suitable for the power distribution system of power users such as substations, power plants, factories and mines, etc., with AC 50Hz, rated working voltage 380V, and rated working current 1000-3150A, as power, lighting and power generation and distribution equipment. Conversion, distribution and control purposes.

PGL cabinet:

PGL type AC low-voltage power distribution cabinet is suitable for power users such as power plants, substations, industrial and mining enterprises as power conversion in power distribution systems with AC 50Hz, rated working voltage 380V, rated current up to 2500A, lighting and power distribution equipment. , Distribution and control purposes. The product has a high breaking capacity and a rated short-time withstand current of 50kA.

PGL type AC low-voltage power distribution panel is divided into: low-voltage metering cabinet, low-voltage incoming line cabinet, capacitor compensation cabinet, city power conversion cabinet, bus connection cabinet, low-voltage outgoing line cabinet

GCS, GCK, MNS, GGD switchgear difference

GGD is a fixed cabinet, GCK, GCS, MNS are drawer cabinets.

The drawer push mechanism of GCK cabinet is different from that of GCS and MNS cabinet;

The GCS cabinet can only be used as a single-sided operation cabinet, and the depth of the cabinet is 800mm.

The MNS cabinet can be used as a double-sided operation cabinet with a depth of 1000mm.

Advantages and disadvantages of various types of switch cabinets

Generally speaking: the withdrawable cabinet saves space, is easy to maintain, has more outlet circuits, but is expensive; while the fixed cabinet has fewer outlet circuits and occupies more land. If there are too few locations provided by the customer, the ones that cannot be fixed should be changed to pull-out ones.

GGD type AC low-voltage switchgear: This switchgear has the advantages of reasonable structure, convenient installation and maintenance, good protection performance, high breaking capacity, large capacity, strong segmentation ability, strong dynamic stability, and wide applicability of electrical solutions. It can be used as Replacement product use.

Disadvantages: There are few circuits, the units cannot be combined arbitrarily and the floor space is large, and they cannot communicate with the computer.

GCK switchgear has high breaking capacity, good dynamic and thermal stability, advanced and reasonable structure, flexible electrical scheme, series, strong versatility, and any combination of various scheme units. One cabinet can accommodate more circuits, save floor space, have high protection level, safety and reliability, and convenient maintenance.

Disadvantages: The horizontal busbar is located on the top of the cabinet, and the vertical busbar has no flame-retardant plastic function board, and cannot communicate with the computer.

GCS low-voltage withdrawable switchgear: It has high technical performance indicators, can meet the development needs of the power market, and can compete with existing imported products. The new low-voltage withdrawable switchgear designed according to the principles of safety, economy, rationality and reliability also has the advantages of breaking, high connection capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, strong series and practicability, and novel structure. Features such as high protection level.

Disadvantages: The dynamic and static contact connectors are not in close contact, prone to heat generation, eddy current, and looseness.

Advantages of MNS series products: compact design: more functional units can be accommodated in a smaller space.

Strong structural versatility and flexible assembly: C-shaped profiles with a modulus of 25mm can meet the requirements of various structural forms, protection levels and use environments.

Adopting standard module design: standard units can be formed for protection, operation, conversion, control, adjustment, indication, etc., and users can choose and assemble them arbitrarily according to their needs.

High technical performance. The main parameters have reached the contemporary international technical level.

Compress the field. The high degree of modernization can greatly compress the storage and transportation prefabricated site.

Assembly is easy and requires no special complexity.

【common sense】

The enclosure protection level of GCS products is IP4X, and the protection level between compartments is IP2X.

IP4X: It can prevent metal wires with a diameter greater than 1mm or narrow objects with a thickness greater than 1.0mm from entering the cabinet;

IP2X: Can prevent fingers or objects with a diameter larger than 12.5mm from entering other compartments.

The enclosure protection level of GGD products is IP3X.

IP3X: It can prevent tools and wires with a diameter or thickness greater than 2.5mm from entering the cabinet or sheet metal frame fabrication.

The protection level of MNS low-voltage withdrawable switchgear can reach IP54.

IP54: It can prevent dust and water from entering the cabinet under splashing conditions.